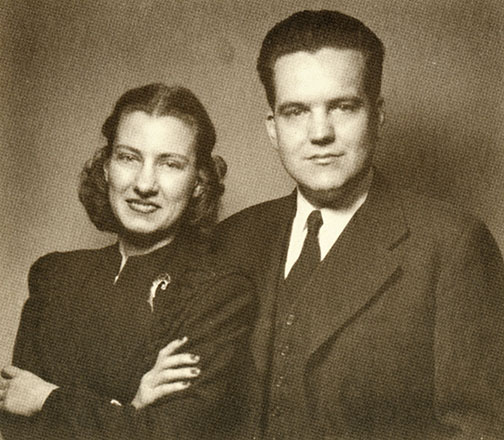

From humble beginnings in 1944 in the back of their home in Hampton, Virginia, Charles and Mary Hastings built their instrument company into a multimillion dollar international business. |  |

Charles Hastings, born in 1914, developed a fascination with building and repairing radios as a young boy. He continued this fascination by studying electronics at John Hopkins University, graduating in 1935 with a degree in Electrical Engineering. He joined the National Advisory Committee for Aeronautics (NACA) the forerunner of NASA. In 1939, Mary Comstock joined NACA as a mathematician, and was assigned an office close to Charles Hastings'. Charles worked fast and they were married in 1940. |  |

One of the NACA projects that Hastings worked on was measuring hte speed of aircraft. He developed a heated thermocouple whose output changed as it was cooled as it moved through the air. It worked great at low speeds, but not a the higher speeds (250 mph) that were typical for the aircraft NACA was investigating. He then applied his radio skills to develop a method to measure the phase shift of a signal superimposed of radio waves transmitted between the aircraft and a ground station. The system worked but NACA chose to use a method related to the new Radar system that was just becoming available.

|  |

Disappointed that NACA did not use either of these ideas, and realizing that both ideas had commercial possibilities, Hastings asked NACA to allow him to pursue them on his own. NACA policy at that time was to allow employees to pursue and patent ideas they had developed as long as, NACA retained the right to use them at any time without having to pay any royalties and as long as it did not violate any confidential security concerns. |  |

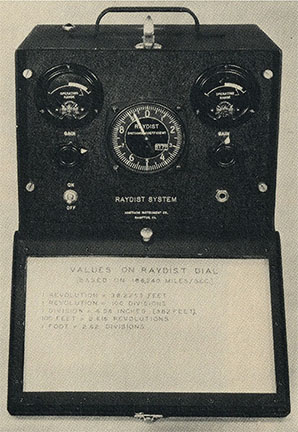

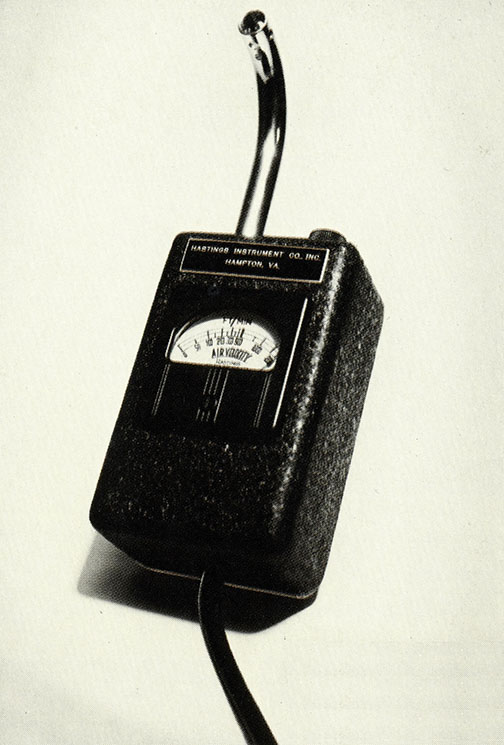

Hastings worked at night on these ideas out of his home, adapting the radio wave system to accurately measure distance rather than speed. He called the system Raydist. In 1944 he formed Hastings Instrument Company (HICO) in his home, with only a few friends working part time in the evenings. In 1945 he introduced his first product, an anemometer based on the heated thermocouple idea he developed. |  |

He called it Air Meter. The instrument had a black crackle finish and the paint had to be dried in Mary Hastings Kitchen oven. The first calibrations were obtained when Mary drove her car down Pembroke Avenue at fixed speeds and her assistant marked the speeds on a blank dial face. Later a tank vacuum cleaner was used as a mini wind tunnel with a hand calibrated Air Meter as a reference. |  |

In 1946, Hastings left NACA to devote full time to his new business. In the early years, Air Meters only accounted for about 10% of HICO sales. Raydist accounted for most of the sales, small as they were, and most of the growth. The Hastings home was becoming so congested with all the equipment and part time people that they had to find another location. The first building was large enough but the roof leaked and it flooded during storms. |  |

In 1948, they found a better building that allowed for current needs and future growth. That same year, Hastings convinced his friend, Ray Doyle, to join the company as a Production Superintendent in charge of personnel, security, purchasing, and all the shops. |  |

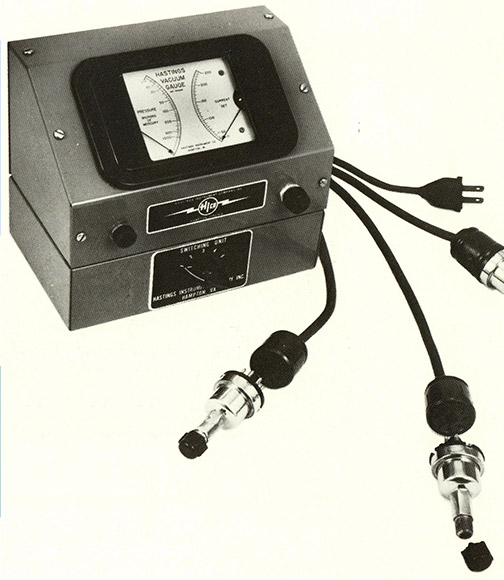

Hastings collaborated with his friend, Jim Benson, to extend the use of the heated thermocouple to measure vacuum. The idea being that the output of the TC would increase as the vacuum increased because there would be less gas to carry the heat away. Benson was attending Tennessee University at the time working on his doctorate. After graduating, Benson joined HICO in 1951 as Vice President and Director of Research. |  |

The Air Meter design was expanded to include flow meters by placing the heated thermocouple inside tee fittings. The flow meters were fast and had very little pressure drop, but the output was non linear and very dependent on gas composition. |  |

In 1954, Ray Doyle was put in charge of HICO's Thermal Instrument Division which consisted primarily of Air Meters, Flow Meters, and Vacuum gauges. Thermal instrument sales were only $70K compared to Raydist sales of $660K. Doyle, assisted by Charlie Hawk, set up a network of domestic manufacturers' representatives. Financial difficulties that year forced layoffs and the consolidation of all operations into one building on Newcombe Avenue and in 1956 the company name was changed to Hastings-Raydist. |  |

The Thermal Instrument division thrived. In 1955 their sales accounted for only about 9% of total sales, but in 1956 this rose to 40%, and in 1957 it was 51%. For the first time, Thermal Instrument sales exceeded Raydist sales. |  |

The major contributor to this spectacular growth was the new vacuum gauge. There were many companies supplying sophisticated equipment to the Manufacturers in newly emerging vacuum fields which required gauges to measure the vacuum produced or required by their equipment. Hastings-Raydist offered to provide the vacuum gauges to these equipment manufactures with their name and logo on dial face. Thus, names like Stokes, Vactronic, Ultek, Sergeant-Welch, CHA, Thermo Electron, and other enjoyed this private label arrangement. |  |

In 1958, the vacuum product line received a major boost when the Atomic Energy Commission selected Hastings-Raydist to provide the vacuum gauges for their nuclear energy and weapons program. In 1960, Hastings introduced the compact vacuum gauge. The circuit was transistorized, placed on a PC board, and mounted directly on the back of the meter. This was ideal for the many customers who wanted to mount the gauge directly on their equipment using the minimum space. |  |

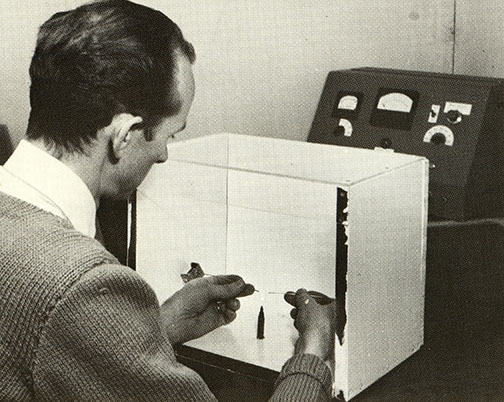

In 1961, Jim Benson, and his assistant Bill Baker, developed and patented a new type of flow meter based on heat capacity. In a sense, it sill utilized a heated thermocouple except that one of the TC materials took the form of capillary tube through which the gas passed. Unlike the original Hastings flow meter, the output was linear over a wide range, and gas composition could be corrected for by applying the ratio of the heat capacities. Thus a second major product line was launched. |  |

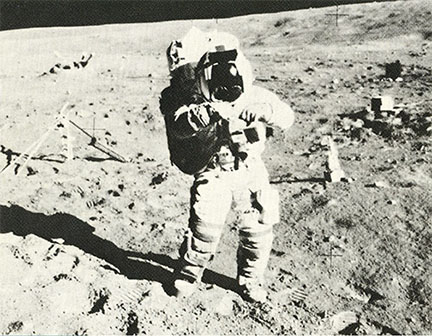

In 1968, Hastings-Raydist was selected to provide the sensor to measure the vacuum in the moon rock box that was to accompany Apollo 11 on the first moon landing. The box, with the Hastings vacuum sensor installed, was sterilized and sealed under vacuum prior to lift off. It was opened on the moon, rock samples were put in the box and it was sealed again under moon vacuum. It was returned to earth and the vacuum was checked with the Hastings vacuum sensor, the seal had not been compromised. |  |